The Internet of Things (IoT) is described in the industrial world as the 4th industrial revolution. The Industry 4.0 concept originates from a German government initiative launched in 2011. The IoT market is estimated to be worth $1.7 trillion by 2020 (according to IDC) and could have an economic impact of $4 to $11 trillion by 2025 (according to McKinsey). These numbers are staggering but encompass different industries and a long value chain (from sensor/chipset to cloud/mobile applications). According to most market surveys, the industrial sector represents the largest potential market for IoT. This post focuses on this vertical and the transformative impact of IoT on business models.

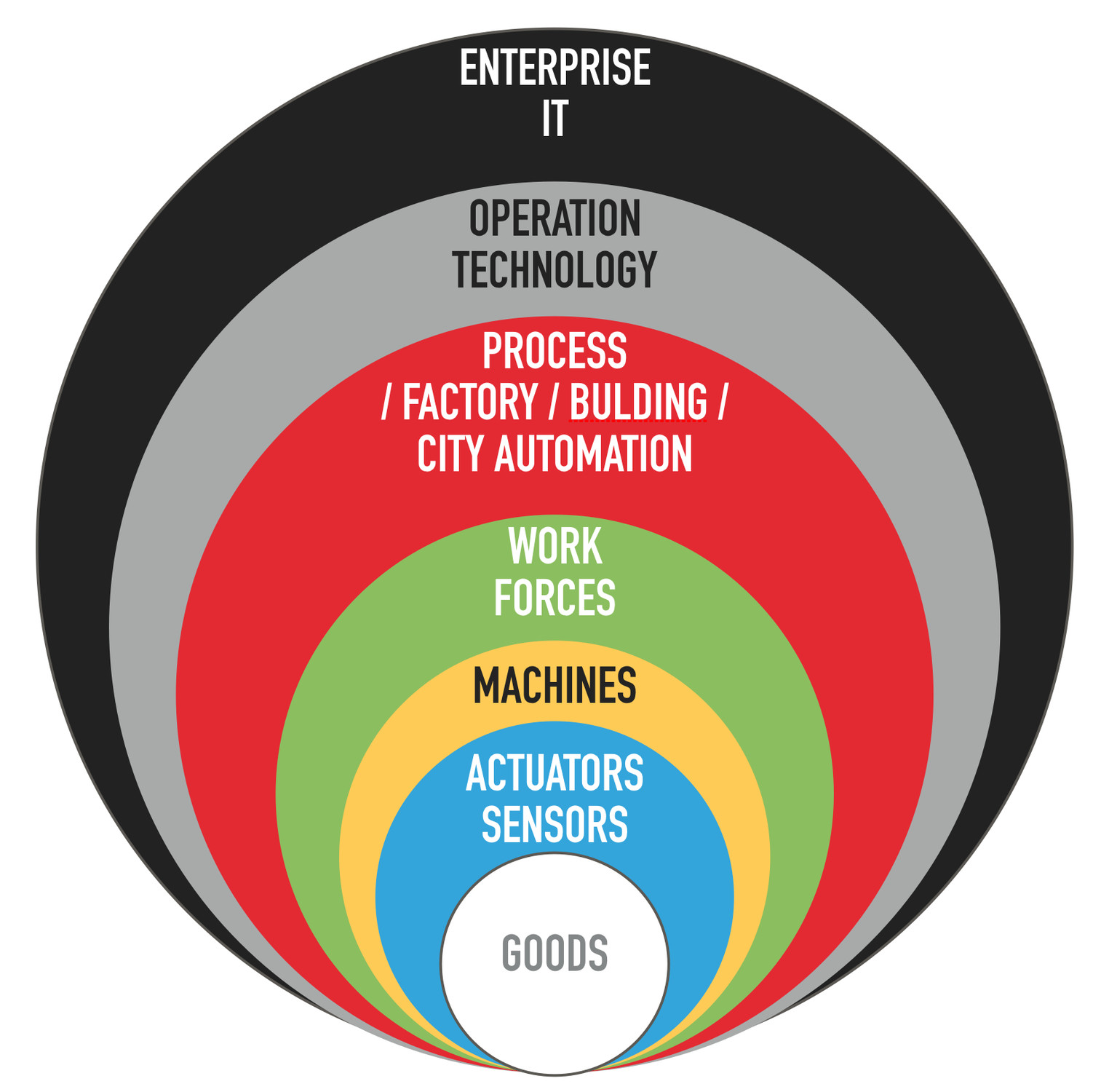

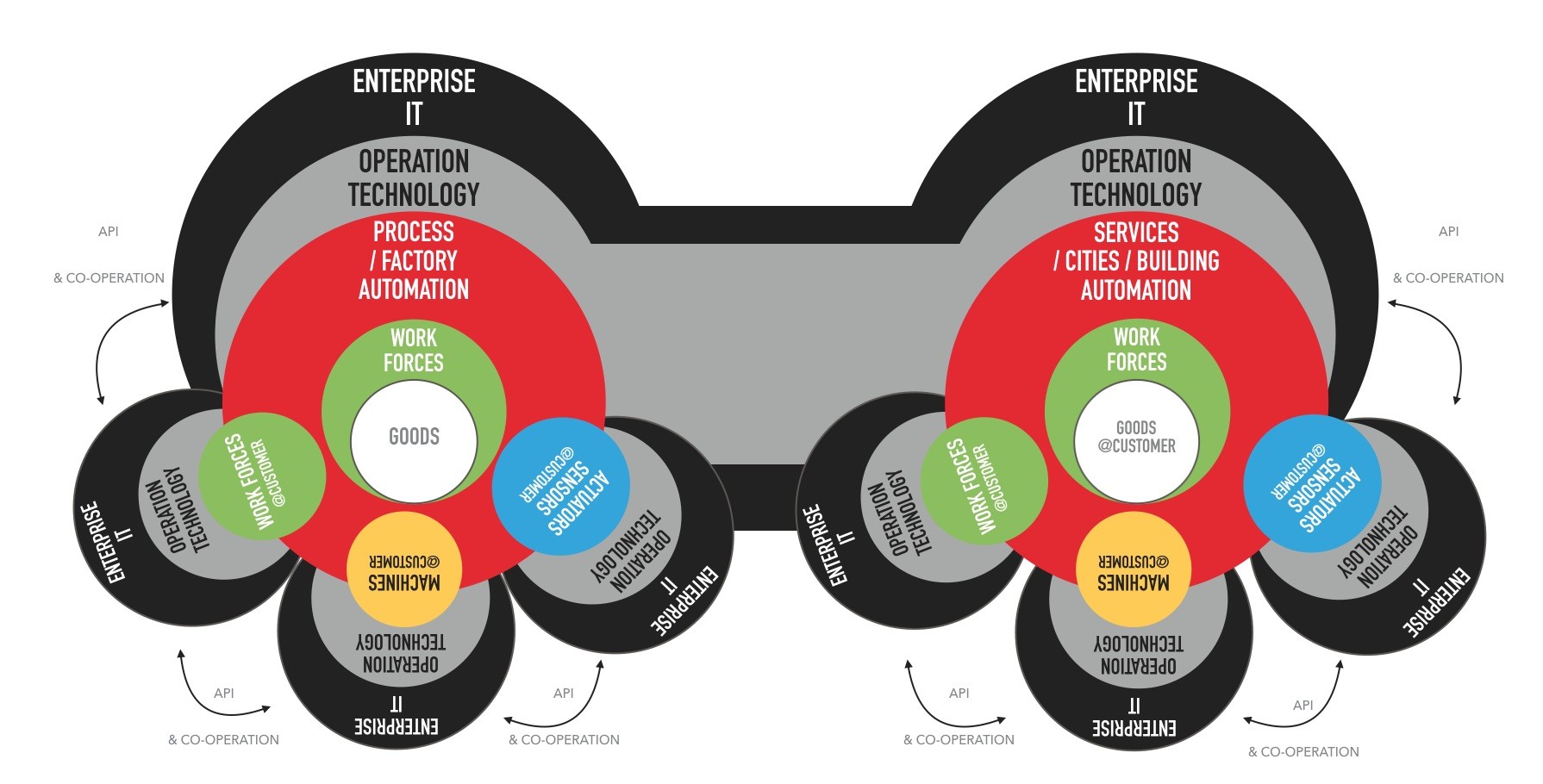

Legacy industrial enterprises are like onions

To understand the changes, let’s first examine the legacy systems. For years, enterprises have been enhancing business operations by assembling in-house technologies. Over time, software became increasingly strategic and now forms the core of enterprise operations (from shop floors to boardrooms).

Most legacy enterprises exhibit the following characteristics:

- Enterprise data are confined within the company IT network, with field data collected, filtered, computed, and reported through various control & IT systems (PLC, DCS, SCADA, MES, BMS, ERP, CRM, etc.).

- Knowledge and competencies are maintained locally or in-house to secure operations.

- The enterprise network acts as the primary security mechanism against external threats.

- Asset suppliers or service providers lack access to field data, with access to equipment involved in mission-critical operations strictly restricted.

- Business operations largely revolve around the manufacturing and distribution of goods.

We saw a significant transformation with the advent of cloud technology in 2006. Cloud technology, particularly BPaaS, SaaS, PaaS, and IaaS models, has driven a major evolution in enterprise software. Most CIOs have integrated cloud-based solutions, and within the next two years, cloud is expected to represent the majority of enterprise software deployments, with a CAGR three times that of on-premises solutions.

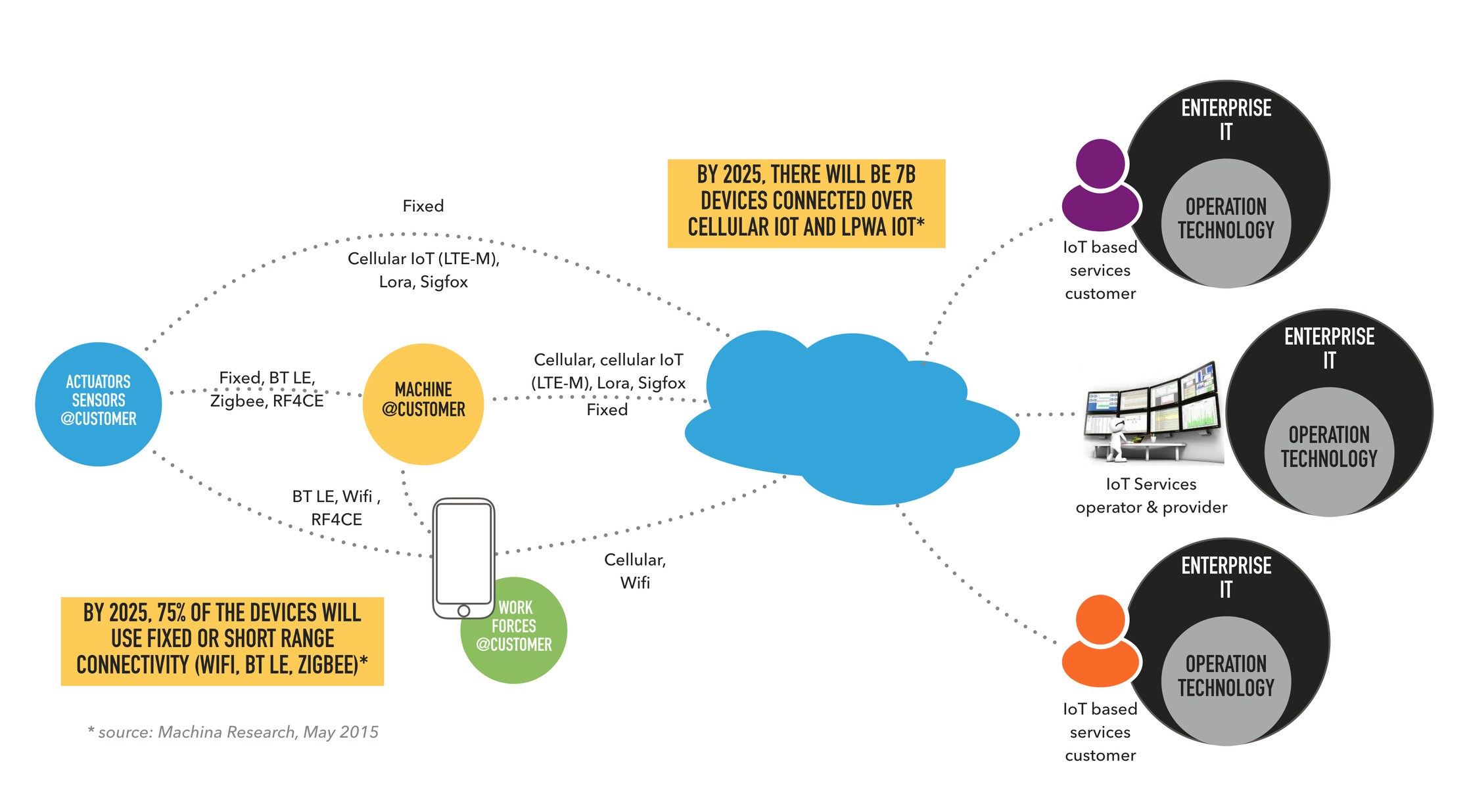

Connectivity, the starting point of the Internet of Things

In 2013, there were already 7 billion machines connected to the Internet, a number expected to reach 30 billion by 2020. When discussing IoT, people often refer to the adoption of M2M, cloud, and mobile technology to enhance enterprise operations. IoT enables asset suppliers and authorized third parties to access physical devices on customer premises (e.g., plants, public spaces). Connectivity is achieved using M2M technology (fixed, cellular, cellular IoT, LoRa, Sigfox) with two main goals:

- Maintain a secure and reliable communication channel between the physical asset and IT applications.

- Bypass local enterprise IT networks to ease asset deployment and maintenance.

Mobile devices and apps have been key drivers of cloud adoption in the industrial sector and will continue to play an important role in IoT adoption by enabling new innovations.

IoT applications in the industrial sector

Industrial IoT applications can be categorized into three asset types:

- Workforces: Operators, technicians, supervisors, engineers, and managers, whether employees or contractors, all contribute to operations.

- Machines: Autonomous assets that perform complex tasks based on information from operators and control systems.

- Sensors and actuators: Assets with basic or no computing power that collect information on the field and pass it to the control system or perform basic actions based on central system requests.

Often, the first use case for connectivity arises from after-sales operations, which are critical for many industrial companies due to their role in maintaining customer loyalty. Connectivity allows after-sales support teams to address issues such as:

- Lack of data when a customer reports an incident.

- Lack of manpower as only a few individuals possess the required skillset for complex issues.

- High costs and operational disruptions from on-site interventions, especially in remote locations.

- Need for asset monitoring to analyze issues and identify root causes.

- Long deployment times for changes or corrective actions requiring on-site presence.

- Difficult demand forecasting for spare parts due to limited knowledge of the installed base and customer applications.

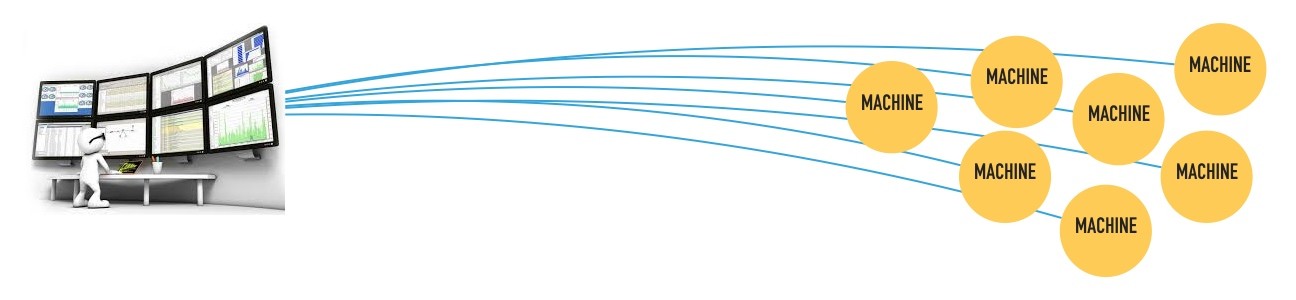

Product teams and sales departments figured out quickly the potential associated with such connectivity. Thanks to the analysis of field data, they are indeed able to gain a deeper understanding of their customer activities and to build product/application knowledge faster than before.

By connecting products, suppliers can build value-added services that enhance their assets

IoT is changing the HARDWARE industry in the same way CLOUD technology changed the SOFTWARE industry. With connectivity, the nature of the customer relationship evolves. The asset supplier enters in a long term and continuous relationship with its customers and by doing so create a more "customer centric" organisation.

Armed with data and statistics, it becomes possible for the physical asset provider to move towards service-oriented business models with confidence without expose itself to a major financial risk.

Here are some examples of such services:

- Asset tracking, remote monitoring, and control

- Preventive maintenance, remote diagnostics, reconfiguration, and updates

- Enhanced HMI with mobile apps

- Performance analytics and cross-customer analytics

- Digitization and virtualization of physical assets

These added value services, often primary developed by the after-sales team, are the building blocks that will enable the supplier to automate its service delivery and by doing so create and scale brand new business models. In this new competition landscape, the players with the largest number of connected devices, the best analytic, and the largest number of customers per asset will enjoy a unique competitive advantage.

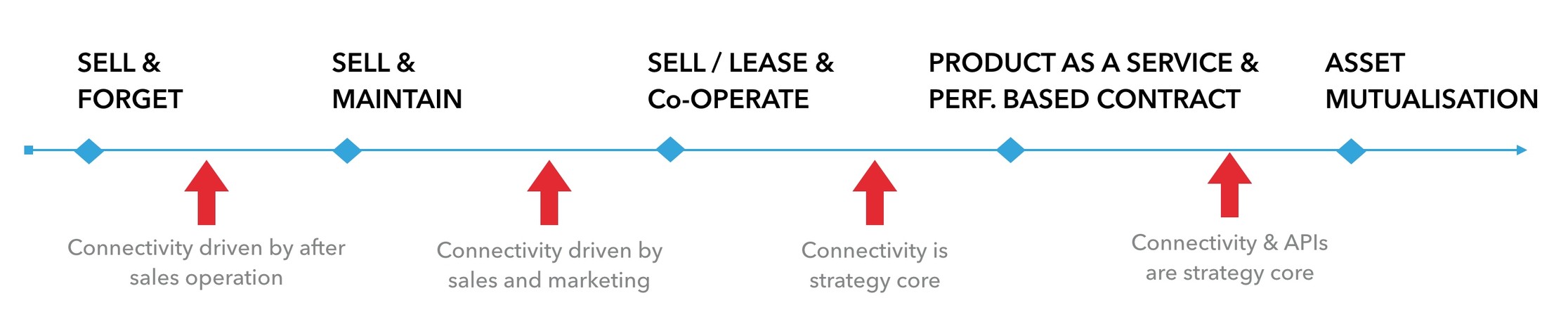

Connectivity enables service-oriented business models

IoT is transforming the hardware industry in much the same way cloud technology revolutionized the software industry. With connectivity, customer relationships evolve, enabling suppliers to move toward service-oriented business models confidently. We can outline five steps in this evolution:

- SELL & FORGET: The supplier provides the asset with only basic after-sales support.

- SELL & MAINTAIN: The supplier provides maintenance and support services in addition to the asset.

- SELL/LEASE & CO-OPERATE: The supplier and customer enter a long-term relationship, managing the asset jointly under an agreed SLA.

- SELL & OPERATE, PRODUCT AS A SERVICE: The supplier commits to the customer’s business outcomes, taking accountability for asset productivity and potential liability.

- ASSET MUTUALIZATION: With customer consent, asset suppliers can provide additional digital services to third parties, lowering ownership costs for the physical asset.

To stay competitive, asset manufacturers must explore how connectivity can enhance their product features and enable new services.

With IoT, enterprises become more interconnected

Maximizing connectivity benefits while scaling IoT business models requires service automation using advanced analytics and AI technologies. APIs facilitate automated data exchange, benefiting both asset suppliers and customers.

Modern industrial companies will focus as much on operational technology for managing installed assets and optimizing service delivery as on traditional control layers (PLC, SCADA). A new, parallel data flow will emerge as virtualized assets expose advanced services to authorized Third Party IT systems.

IoT will contribute to build a healthy P&L based on a combination of HW, SW, and Services sales. Integration of data flow and transactions with other asset owners or asset suppliers will become mandatory to survive and scale in this hyperconnected world.

The race is on!

IoT adoption will drive profound changes in product design, asset management, and operational practices. Just as it took nearly a decade for cloud technology to become mainstream, it will take time for IoT to achieve similar traction.

Business models like Product as a Service will be key drivers.The next major step in productivity and innovation is underway, and the race is on!